Example

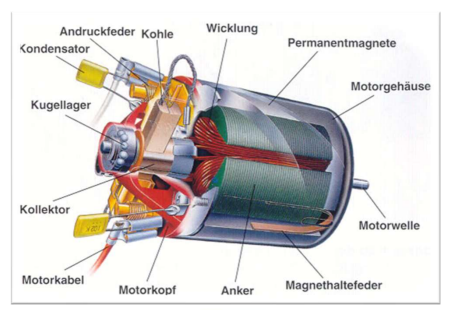

Direct current motors (DC-motors)

- Up to 98% efficiency

- Power cord or battery

Brush motor:

- cheap

- Mature technology

- Sparking / high-frequency interferences

- Life limit – carbon brushes

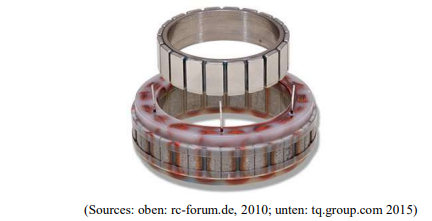

Brushless motor:

- More efficient / less heat

- Less wear

- More power per weight

- Requires a controller

Stepper Motors

-

Revolutions will be made in an amount of steps (degree), not as a constant movement, exact positions can be achieved

-

Bipolar: 2 coils 4 connections (more power per motor-volume)

-

Unipolar: at least 5 connections, simpler control

-

Reluctance motor

- toothed soft iron structured rotor

- No permanent magnets

- Free magnetic flow, no magnetic field after switched off

-

Permanentmagnet motor

- Permanentmagnet on the shaft / Stator made of soft iron

- Moment of rest

- Lower resolution in comparison to ther reluktance motor

-

Hybridmotor

-

Permanentmagnet and toothed soft iron core on the shaft

-

Servos

- Analog servos

- Low power consumption

- Low price

- Digital servos

- Faster positioning time

- Higher resolution

- Partly programmable

- PWM-control

-

Common for hobby servos

-

Servo elektronics regulate the actor (potentiometer) against the motor position

-

The pulse width of the control signal regulates the target position

-

Various variations on pulse widths and travel ranges

-