Terminology

-

Bus System – Communication System between a controller and several attached devices e.g. Can

-

Load – a load connected to the actual actuator [Watt]

-

Piston – an pneumatic or hydraulic actuator for linear movements • Position control – moving an actuator by position informations

-

Rotor – moving part of an electric motor (anchor)

-

Rpm – revolutions per minute

-

Speed control – moving an actuator by actual speed values

-

Stator – Static part of an electric motor (coil)

-

Shaft – connection of a rotating or a linear actuator to their environment

-

Torque – M = r * F / torque = position vector x force vector [kg m^2 s^-2]

Motor

Example

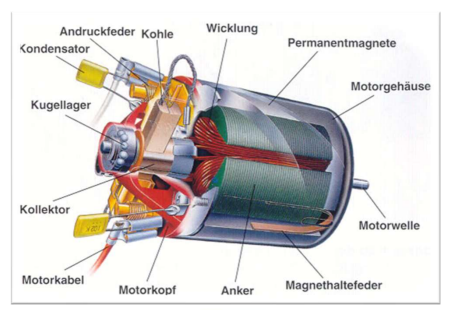

Direct current motors (DC-motors)

- Up to 98% efficiency

- Power cord or battery

Brush motor:

- cheap

- Mature technology

- Sparking / high-frequency interferences

- Life limit – carbon brushes

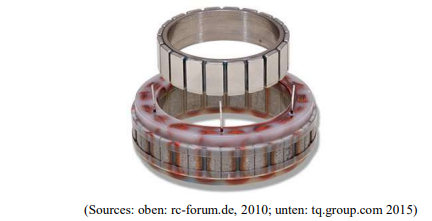

Brushless motor:

- More efficient / less heat

- Less wear

- More power per weight

- Requires a controller

Stepper Motors

Revolutions will be made in an amount of steps (degree), not as a constant movement, exact positions can be achieved

Bipolar: 2 coils 4 connections (more power per motor-volume)

Unipolar: at least 5 connections, simpler control

Reluctance motor

- toothed soft iron structured rotor

- No permanent magnets

- Free magnetic flow, no magnetic field after switched off

Permanentmagnet motor

- Permanentmagnet on the shaft / Stator made of soft iron

- Moment of rest

- Lower resolution in comparison to ther reluktance motor

Hybridmotor

Permanentmagnet and toothed soft iron core on the shaft

Servos

- Analog servos

- Low power consumption

- Low price

- Digital servos

- Faster positioning time

- Higher resolution

- Partly programmable

- PWM-control

Common for hobby servos

Servo elektronics regulate the actor (potentiometer) against the motor position

The pulse width of the control signal regulates the target position

Various variations on pulse widths and travel ranges

Link to original

Hydraulics

Energy density:

210 bar (Industry standard)

500 barAdvantages

- High power density

- Good controllability

- Good timing behaviour due to low inertia

- Simple and reliable protection against overload

- Good energy transmition over medium distances

- Good lubrication and dissipation of the heat loss through the pressure transmission medium

Disadvantages

- High energy consumption

- High weight of drive and control elements

- Losses from friction and internal leakage

- Sensitive to dirt

- Fire hazard

Motor

Link to original

Pneumatics

Advantages

- The forces and speeds of the cylinders are infinitely variable.

- High achievable working speeds (standard cylinder 1500 mm / s; high-performance cylinder 3000 mm / s, engines up to 100.000 min-1)

- Compressed air devices can be overloaded to a standstill without damage.

- Compressed air can be stored in pressure tanks.

- With pneumatics, waste heat is only generated centrally at the compressor, not at decentralized electric drive units.

- Air is free of charge and always available (however, energy consumption at the compressor is required to compress the air; the efficiency is comparatively low).

- Clean, environmentally friendly medium.

- The exhaust air can escape directly into the environment, return lines can be omitted.

- Explosion safety of the medium is guaranteed.

- Compressed air is insensitive to magnetic impulses.

- Sealing and throttling technology possible (sine cylinder).

Disadvantages

Link to original

- Without fixed stops, precise positions are not possible due to the compressibility of the air.

- Compressed air escapes causing noise. Countermeasures are silencers.

- Compressed air treatment is required to remove dirt and moisture.

- Gases are compressible. Bursting pneumatic accumulators release large gas volumes. This can have a devastating effect, especially in closed rooms. For this reason, pneumatic containers are subject to regular inspection (costs) from a certain size.

next: RDL VL 13 Electronics